Offshore software development is no longer a cost-cutting play but a strategic growth lever for American companies. The Global Outsourcing Survey 2024 by Deloitte reveals that more than 76% of organizations now outsource IT functions, with coding, UX/UI design, and quality assurance (QA) as leading areas.

Working with virtual or offshore development teams is as common in the technology space as having fries with your hamburger. The top two reasons American companies outsource mobile app development are to accelerate time-to-market and unlock specialized expertise that is scarce domestically. According to the IT Outsourcing: Market Data & Analysis 2024, the IT outsourcing market is predicted to expand substantially, reaching a market volume of US$295.06bn by 2030.

Today, when competition is fierce, launching late or building subpar digital products can cost millions. That’s why forward-looking US companies are partnering with offshore development teams to de-risk delivery, accelerate outcomes, and fuel innovation.

With an offshore development strategy complementing your in-house development team, organizations that know how to work with offshore teams effectively gain a serious competitive edge. But let’s be honest, managing an offshore workforce isn’t frictionless. The greatest worry on every executive’s mind is how to work with offshore teams effectively and productively.

Managing offshore teams does not necessarily mean endless video calls, chasing updates at odd hours, and praying deadlines survive the time-zone gap. What if I told you there is a series of actionable steps you can take that are guaranteed to help you make the most of your partnership with offshore agencies?

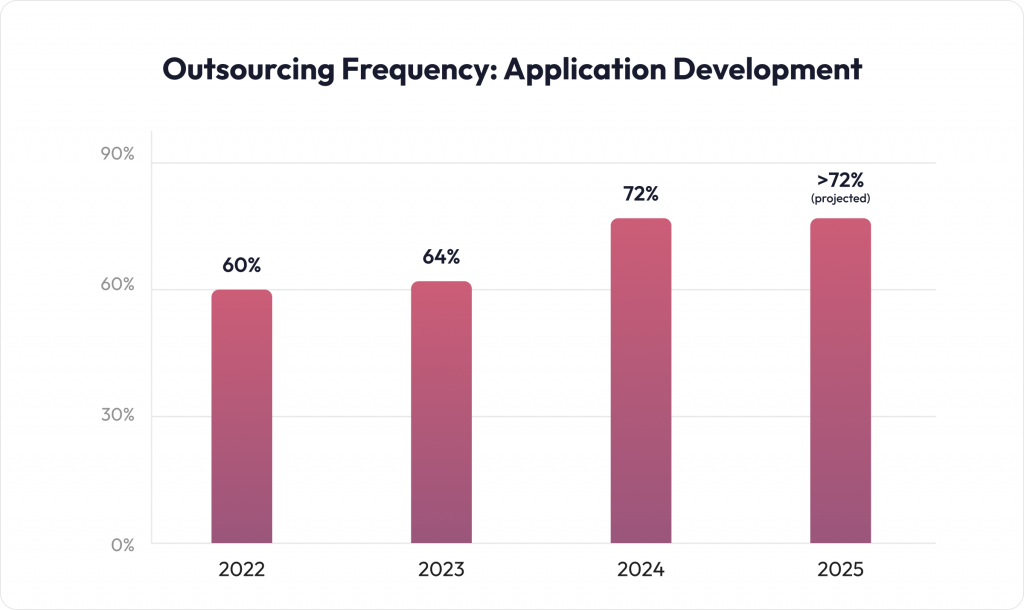

Source: Krusche & Company, Avasant Research, Deloitte’s Global Outsourcing Survey

In this blog, we’ve shared 17 actionable strategies—backed by our experience working with some of the biggest brands in the world to create mobile apps, websites, and integrated systems—to help you navigate the complexities of offshore team management.

Our considerations and recommendations are platform, agency, and country agnostic. We look at big-picture strategic considerations, along with process and day-to-day implementation strategies, to help you get the maximum ROI when working with offshore teams.

If you are a US executive seeking answers on how to work with offshore teams, explore the strategies you can use to build stronger partnerships, de-risk delivery, and drive results.

Big picture

There are various considerations every product leader should note when working with offshore teams to build and launch a great digital product, whether your teams are collocated in San Francisco or across the world. Let’s look at some of the big picture differentiators for managing offshore teams.

1. Share a clear product vision

Managing offshore teams effectively starts with leaders aligning teams on vision, culture, and engagement, before diving into deliverables or tools. Without this alignment, even the most talented offshore resources risk pulling in different directions.

Bring out the big picture by articulating your vision. It is about clearly communicating:

- Overall goal (e.g., improved retention)

- The product differentiator

- KPIs that will define success

These are all critical factors that make the difference between a poor and a great partnership with your remote team.

Source: AZQuotes.com

Once the ink on a partnership contract has dried, and you’ve selected your implementation partner, virtually all companies and their remote partners go through the same first step: understanding what the client aims to build.

In this step, the person or company contracting with a strategic partner has the first opportunity to introduce their objectives, needs, and goals formally.

Too often, technology clients view remote or offshore development teams merely as the execution partner for a specific feature, function, or system. However, it’s important to note that fundamentally, people work with people. The more clearly you share your vision about what you want to build and why, the more invested your strategic partner can become in a specific idea or concept for its effective execution.

That’s why the most successful mobile app products worldwide have amazing visionaries behind them. From the moment you start engaging with an offshore development team until the end of the partnership, you should always have a clear vision of your project that you consistently and constantly communicate to the people you work with – be those internal resources or outsourced team members. You must ensure that your offshore development teams have clarity on macro-outcomes (time-to-market, customer adoption, revenue impact) and micro-level KPIs (velocity, bug density, adherence).

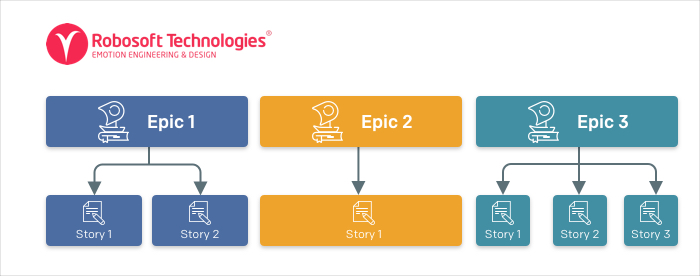

This image summarizes how to convey your vision to your team best:

In short, your overall vision of the project is key to its success. When working with an offshore software development team, articulating your idea, vision, and product differentiator becomes even more critical. To be successful, you want people to believe in and become invested in your vision.

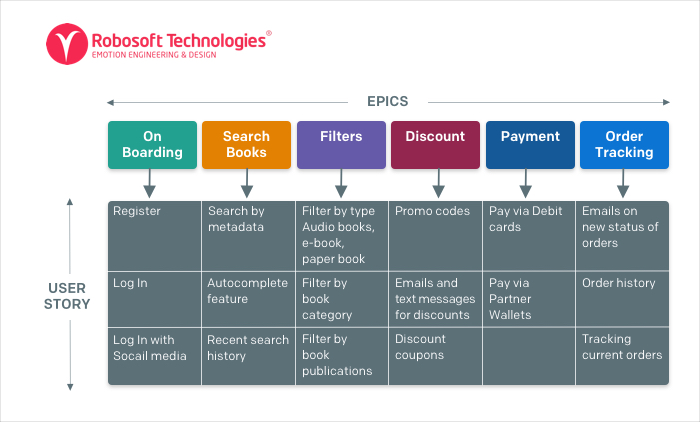

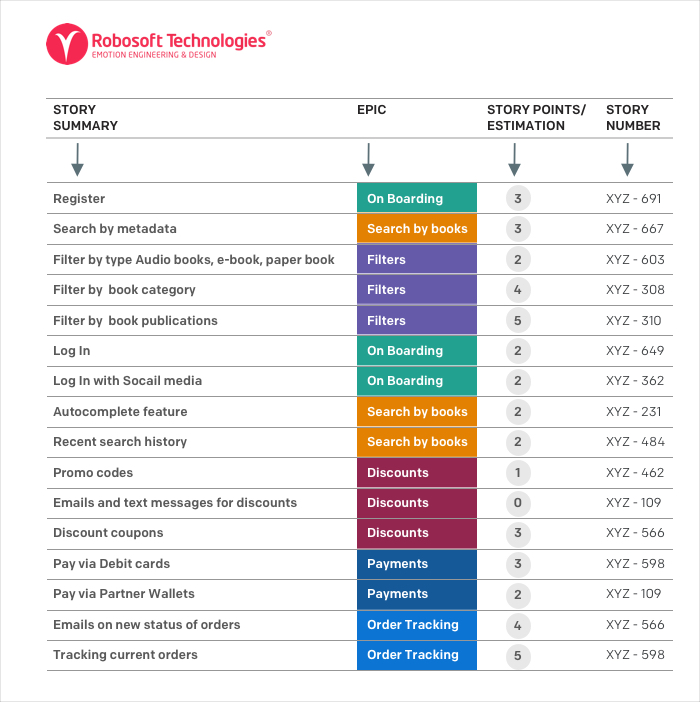

2. Define specific requirements

Most developers we have met are analytical, organized, and thorough. If you provide them with clarity in requirements (detailed user stories, wireframes, acceptance criteria, and documentation), they will work hard to deliver a product that meets your specifications.

Ambiguity works like a downward drag for offshore development teams or remote teams. If the vision is the catalyst for the overall success of your digital product, clearly conveying what you want is the engine for achieving each milestone required to build the overall product.

Emotional investment and effort from the client’s side are required to effectively communicate (more on that later) with offshore team members and to articulate, through various means (covered below), what remote team members are responsible for from an execution point of view.

3. Establish success criteria early

Knowing what you want from your offshore development team wins only half of the battle. If everyone is to stay on the same page, clients and remote teams need to align themselves with the specific criteria for success.

This is true for the overall success of your project and the intermediary milestones that need to be met along the development path. Most mobile app development projects take between two and six months. If we accept Murphy’s law, “anything that can go wrong will go wrong during that timeframe.”

It is paramount to clearly define success criteria upfront to avoid any discontent when working with offshore teams. The image below shows some of the main factors that can impact a project’s success and that you should spend considerable time defining and monitoring.

Competent technology partners and great offshore consultants will discuss and mention some of these factors, such as setting expectations, proper planning, milestones, etc., as dependencies.

Remember, though, that success is a two-way street. That’s why it is the client’s job to communicate project objectives and requirements clearly and always be available in a timely fashion for questions and clarifications that may impede your offshore development team members.

The client and the offshore software development teams are in this together, and both are responsible for the overall success of any project, bringing us to our next point.

4. Build a unified culture for cross-team synergy

You’d agree that one of the hardest aspects of offshore team management is cultural integration. Whether you work with internal, collocated resources, or offshore software development teams, it is crucial to create a culture of belonging. Most companies and executives fail to realize that this concept is important whether a person is a contractor, full-time employee, or a third-party agency providing technology services.

Ultimately, everyone is working towards the same goal. If a product is successful, everyone wins—together. We think every client needs to own and promote this winning attitude as part of their engagement with dedicated offshore teams.

It doesn’t matter whether a person is sitting in San Francisco, Bangalore, or Bucharest. What matters is that everyone is aligned behind the same vision and set of goals.

Cultural integration is leadership-driven and crucial for cross-team synergy. Thus, creating a unified culture of belonging across borders, time zones, and employment statuses is a product of leadership.

As the owner of a project, you should make it your mission to ensure that every single person contributing to the product success feels included, appreciated, and part of your greater vision.

Strategic considerations

All the tips and recommendations in this section relate to issues and opportunities that arise specifically because your resources are not collocated.

Working with offshore development partners can sometimes lead to disagreements, miscommunication, missed expectations, and a culture of distrust.

To avoid these unfavorable situations, it is paramount to pay close attention to these issues BEFORE you engage an offshore development team, independent consultant, or offshore mobile app development agency.

5. Hire offshore teams you can trust

Trust is the foundation of any strategic partnership, and it applies for offshore relationships as well. Without it, executives spend too much time second-guessing and oversight overhead increases. So, you should consider the following:

- You must hire people and companies you trust.

- You must trust they will do what is best for your company and product.

- You must trust that your offshore partner will work toward shared success to make your product successful.

When you’re managing offshore development teams, this factor becomes incredibly important. After all, things often get lost in translation – and we don’t mean in a literal way. We mean that with people working in different time zones, most communication is in written form. Talking to someone in person gives you a completely different experience because 55% of communication is nonverbal. However, communication with offshore software development teams is mainly done in a written format – emails, chat sessions, and project management tools. This, in turn, opens the door to misinterpretations, incomplete information, and, sometimes, distrust of your offshore resources.

Clients who select an offshore vendor or team member should only sign on the dotted line if they fully trust that partner. Anything less will lead to uncomfortable interactions, bad faith, and project failure.

6. Respect offshore team’s expertise

With trust comes respect. You cannot have one without the other. With your offshore resources you should absolutely have both.

In the many interactions between a client and an offshore team, there will be countless times a problem can be solved in multiple ways. Some clients and employers feel the need to be very hands-on with their offshore resources. No one says a hands-on approach is bad – but clients should only exercise this right within reason.

After all, you’ve hired a team or a distributed resource for their skills, qualities and past achievements. It’s highly important for remote resources to feel their input is valuable and that they are trusted to make decisions based on their professional judgment during the implementation of a feature.

When team members feel their input is valuable, they are more likely to take initiative, emotionally invest in your project and go the extra mile to deliver on their promises.

7. Select teams with relevant industry experience

When it comes to working with dedicated offshore teams, it is often smart to stick with what you know. In other words, it makes perfect sense to select a strategic partner with previous experience working on similar industries and projects.

If an offshore development team or consultant has successfully delivered on similar projects in the past, it is a good indicator that they can deliver successful results crafting your project.

As we mentioned in our guide on how to choose the perfect technology partner, most consultants and remote development teams will gladly provide client contact information with you, so you can check their references. If they refuse or otherwise stall when you ask for references, it’s downright suspicious, and a huge red flag.

In short, when it comes to choosing offshore development teams, it sometimes makes sense to do business with companies and employees previously in that situation. If they’ve successfully worked from a remote position with similar clients and have delivered good quality work for companies that launched products similar to yours, they will do the same for you.

8. Prioritize strong communication practices for collaboration

Great communication is the key to a successful partnership, whether you work side-by-side or in different time zones. It is no different when working with virtual teams or offshore development teams. However, as Luke Watson correctly points out, communication remains the number one issue when working with offshore resources.

Fostering an environment in which communication practices becomes a goal in and of itself is the best way for effective offshore collaboration.

To help offset some of the issues caused by non-collation of resources is to decide how to effectively leverage different communication channels. Here is a ranked list of how to efficiently use various communication methods between onshore and virtual teams:

- Email – use sparingly for project meeting notes, official communication, schedules and commitments

- Chats – always have a chat window open. Use this for quick clarifications, status updates and questions.

- Productivity tools – use the best tools on the market for smooth project management. Whatever tool you choose should be enforced across the team. Having a great project tool reduces friction, improves communication, and documents assumptions about a project.

In short, communication with offshore development teams can indeed be a challenge. However, with the right process and tools set in place, it can absolutely be overcome.

9. Treat your offshore team as true partners

Choosing an offshore company or individual partner is exactly this: teaming up with a partner, someone you respect and who is more than merely a vendor doing business with you. Spend time getting to know the person or the team with whom you will be working.

When working with a partner agency, the conversation naturally revolves around what should be done. That’s totally fine. So, when hiring an offshore development team, you have people working with other people. Beyond simply getting a paycheck, people form connections, become emotionally invested in a project and go the extra mile for the clients and projects they care about. Treating your offshore resources like real partners will pay off in the long run. Every single time!

10. Choose flexible, adaptable teams

Technology is constantly changing. More than a decade has passed since the first iPhone was released. In these seventeen short years, mobile app platforms, frameworks, and programming languages have all significantly evolved. Eclipse gave way to Android Studio; Objective-C made room for Swift. Now, with the rapid growth of AI-powered product development tools, this change is even faster.

So, with technologies evolving at a fast pace, your offshore development teams should stay current with new tools, frameworks, and programming languages. When you have collocated resources, it is significantly easier for your team to attend meetups, conferences, and events that improve their collective knowledge.

Of course, with the proliferation of online courses, one could argue that offshore and remote resources can also gather more knowledge, but it is not the same.

In other words, you need self-driven offshore teams who actively work on different platforms, improve their knowledge on their own and have a broader perspective to view development technologies as tools. They must be flexible, adaptable, and AI savvy.

You want naturally curious, always learning teams and offshore consultants to join your ranks that will infuse your own team and product with fresh and exciting new development perspectives.

When we partnered with Mercury Financial, a U.S. fintech company offering consumer-friendly credit products, the goal was clear: create mobile experiences with fast loading and transaction processing capabilities.

Our offshore team crafted mobile apps for both iOS and Android platforms. We optimized app architecture for better performance. We used modern IDEs-Android Studio and Xcode for developing the apps.

11. Hire companies with representatives in your time zone

With the offshore teams you tap into the specialized, experienced, and cost-effective resources than local hires. Most IT leaders (60%) globally have their software developed by offshore teams (third party vendors and agencies).

One problem remains: if you have an issue or need clarification during work hours, how do you get your answers if the team you’re working with is in a time zone 8 hours or more ahead of you?

To resolve this issue, many vendors have started offering a hybrid model for business engagements. Hybrid model in offshore development refers to the companies with offshore teams and a registered presence in the United States as well as some local resources available within the client’s time zone. Local resources are typically project and product managers, design resources and account managers who are available during local work hours to take questions from a client and act as liaisons between the client and the development team.

This model has become so popular that most vendors with a predominantly offshore presence are now offering it to their American clients. This alternative to the traditional offshore model has made many startup founders feel more at ease with leveraging distributed teams to get their products to market in a speedy and efficient manner.

12. Recognize your offshore team achievements

When you are working with offshore resources, it is natural to simply communicate with them about tasks that need to be completed, timelines, and bug fixes that need attention.

However, don’t limit your interactions to just bug reports and deadlines. It’s important to remember when you partner with offshore resources, you are working with people. No matter where in the world you live, or what your cultural background, positive feedback can go a long way to improving your working relationship.

If the team has done a good job at delivering on time and on budget – express your appreciation. If users love the product, share that valuable feedback with your offshore teams. Treat your distributed teams as you would any other close partner: when something goes well, be sure to tell them so.

13. Maintain a regular check-in cadence

When you are dealing with collocated resources and you need to solve a problem, the solution is really simple. You walk over to the person’s desk and talk about it. Things get a little more complicated when dealing with offshore teams. But they don’t have to be!

Regular check-ins are recommended for any type of project where there are multiple stakeholders and decision-makers. This becomes significantly more important when working with offshore and virtual teams. As other experts have mentioned, a regular cadence of meetings is critical to the overall success of the project.

To get the most out of regular check-ins with your virtual teams, the best strategy is to maintain a very structured approach, so everyone’s time is used effectively.

If you do regular, structured check-ins, you will likely cut through the noise and ensure progress stays on track.

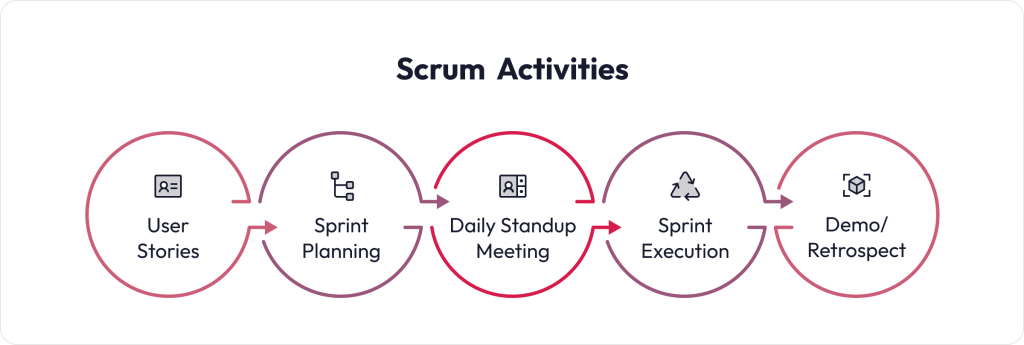

14. Standardize processes across teams

If you are a startup working with only one offshore development team, the process is simple. Always align on a process of engagement: coding practices, testing protocols, and documentation standards, which everyone then executes.

We cannot emphasize enough how important it is for executives to ensure that all resources, offshore and in-house, follow the same processes and transfer deliverables in the same format because a unified process eliminates confusion.

In software development, many steps are done differently by various people unless a common set of practices is put in place. From coding to testing, requirements gathering to production release notes, there are quite a few practices that must be absolutely standardized across teams. As others have mentioned, lack of standard practices in the development cycle is one of the biggest mistakes affecting the cost of software development.

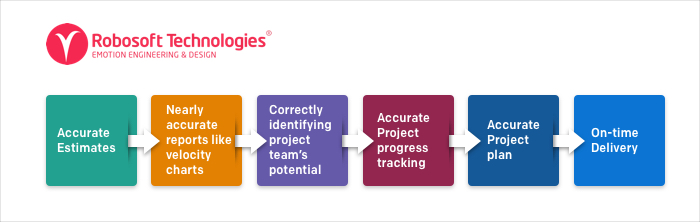

15. Align performance monitoring of your team

One of the most frequent sources of discontent between clients and virtual teams collaborating on the same project is missed expectations. As a client, you expected to see something done in a specific way, but it was delivered in a different manner.

The best way to avoid hard-feelings when working with remote teams is to agree, up-front, on how the performance of the offshore team will be monitored throughout the process.

No one expects every single detail to be outlined in the master service agreement. However, it is incredibly important for clients and service providers to discuss how the performance of a virtual team will be monitored and reviewed throughout the engagement.

There should be alignment between onshore project managers and virtual resources on quantifiable KPIs, task turnarounds and feedback mechanisms, so everyone clearly understands what is expected for each step.

16. Understand the offshore team’s process

Another common source of discontent between clients and offshore resources can involve how and why virtual teams deliver work products in a certain way. Professionals have different methodologies, processes and work methods of which clients may not be aware.

Of course, distributed resources and virtual teams will adapt their work deliverables to the clients’ needs, within reason. However, it always helps if clients and onshore managers are open to understanding and learning the process used by virtual teams.

In a globalized workforce, professionals come together and work on joint projects while sharing different socio-economic and cultural backgrounds. Much of the conflict between clients and service providers is due to a failure to understand the other party’s perspective or why something is being done.

Knowing a virtual team’s work process means meeting them halfway on the path to a long and strong partnership.

17. Use visual communication tools

As we all know, most people are visual learners; 90% of information processed by the brain is visual. That is why this article is a combination of text and summary images – to allow you, the reader, the option of skimming through our recommendations or reading them in their entirety.

The same concept applies to working with remote teams. What you write in an email or chat window, or what you say on a phone call may be subject to multiple interpretations. When you visually show what you expect, people can process that information and produce the necessary deliverable faster and more efficiently.

That is why it is absolutely critical to use tools that can help you convey your point in a visual fashion when working with distributed virtual teams. Luckily, many of these tools are free to use or very inexpensive. Real-time meeting tools have a built-in option for screen sharing.

Ultimately, whatever option you choose is less important than making sure you have an easy and effective method to visually convey your thoughts and desires to your virtual team members.

Final thoughts

Working with offshore software development teams is a strategic imperative. Whether you choose a development partner with an offshore base of operation or decide to hire a professional in a different city, this is an everyday scenario for many companies in America.

Although the benefits of collocated resources are well-known and understood, companies are naturally looking for the best people for a job. Those people may be on the other side of the country or the other side of the world.

We hope you’ll benefit from the best practices for managing offshore resources that we’ve shared in this article.

Working with virtual teams has already been proven successful. The only question should be what you can do to ensure the virtual team model is implemented efficiently. By following our 17 actionable recommendations on how to work with offshore teams, you can build a reliable offshore team that accelerates outcomes and de-risk delivery.